Temperature and humidity are crucial factors in surface preparation, affecting adhesion for painting, coating, and tinting. Optimal conditions (70-75°F/21-24°C, 50-60% humidity) enhance bonding strength, while extremes cause poor adhesion. Proper management prevents issues like blisters and ensures long-lasting protection for materials like glass and metal, vital for specialized treatments requiring UV protection.

In the realm of surface preparation, temperature and humidity play pivotal roles in determining the success of any coating or adhesive application. This article delves into these environmental factors’ intricate dance with surface properties, offering insights that are crucial for achieving optimal results. We explore how understanding temperature’s impact on adhesion complements the often-overlooked role of humidity levels. By establishing ideal conditions, professionals can ensure efficient surface preparation, setting the stage for long-lasting and aesthetically pleasing finishes.

- Understanding Temperature's Impact on Surface Adhesion

- Humidity Levels: The Unseen Factor in Coating Success

- Optimal Conditions for Efficient Surface Preparation

Understanding Temperature's Impact on Surface Adhesion

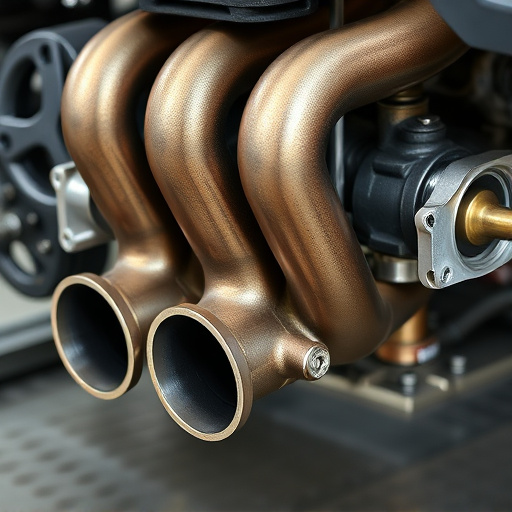

Temperature plays a pivotal role in surface preparation processes, particularly when it comes to adhesion. In general, an optimal temperature range enhances the bonding strength between different materials during application, including essential steps like painting, coating (like ceramic coating or paint correction), and window tinting. However, extreme temperatures can negatively impact this critical aspect of surface prep.

For instance, very hot surfaces may cause certain coatings to set too quickly, leading to poor adhesion. Conversely, cold temperatures can make materials more rigid, hampering their ability to adhere properly. Maintaining a balanced temperature is thus crucial for successful surface preparation, ensuring that the applied layers bond securely and last longer.

Humidity Levels: The Unseen Factor in Coating Success

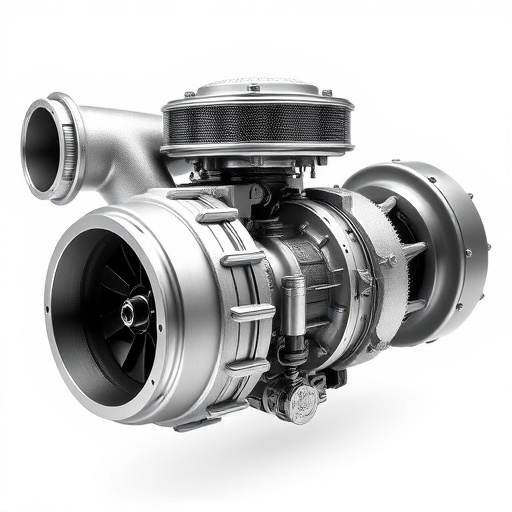

In the intricate world of surface preparation, humidity levels often fly under the radar but play a pivotal role in the success of various coatings and finishing techniques. Humidity, an invisible yet powerful force, can significantly impact the application and longevity of finishes like vinyl wraps, ceramic coatings, and professional PPF (Paint Protection Film) installations. When humidity infiltrates the preparation process, it introduces moisture into the air, which, in turn, affects the viscosity and drying time of coatings.

This unseen factor becomes particularly critical during the installation of protective films or intricate wraps, such as vinyl wraps or PPF. In environments with high humidity, these materials may not adhere properly to the surface, leading to blisters, bubbles, or an uneven finish. Conversely, in low-humidity conditions, coatings can dry too quickly, causing cracks or other defects. Therefore, optimal surface preparation involves carefully managing humidity levels to ensure the perfect application and long-lasting protection for any material used.

Optimal Conditions for Efficient Surface Preparation

Maintaining optimal temperature and humidity levels is crucial for achieving efficient surface preparation. In general, a balanced environment with moderate temperatures and consistent humidity ensures the best results. For many materials, including glass and metal, ideal conditions typically range between 70-75°F (21-24°C) with relative humidity around 50-60%. These parameters promote optimal molecular activity, enhancing adhesion and paint or coating application.

In the context of specialized treatments like ceramic window tinting and custom graphics, precise control over these factors becomes even more critical. UV protection, a key consideration in such applications, is best achieved when temperature and humidity are closely managed. This ensures that protective coatings adhere securely, preventing premature fading or deterioration due to environmental stress.

In understanding how temperature and humidity influence surface preparation, it becomes evident that achieving optimal conditions is key to successful coating applications. By controlling these environmental factors, professionals can ensure superior adhesion, reduce errors, and enhance the overall quality of their work. These insights empower technicians to make informed decisions, resulting in efficient surface preparation that stands the test of time.